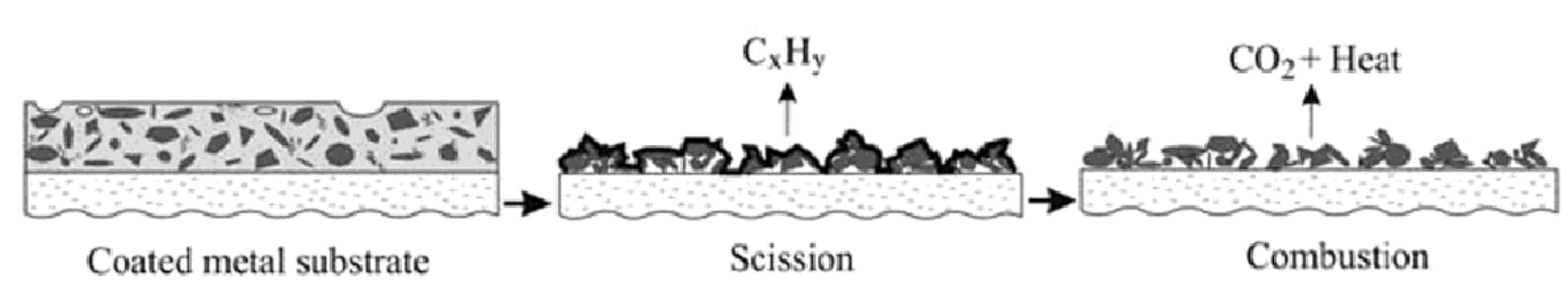

Sheet metal refers to metal that has a high surface area to volume ratio.

Fundamentals on the miniaturization of sheet metal working processes.

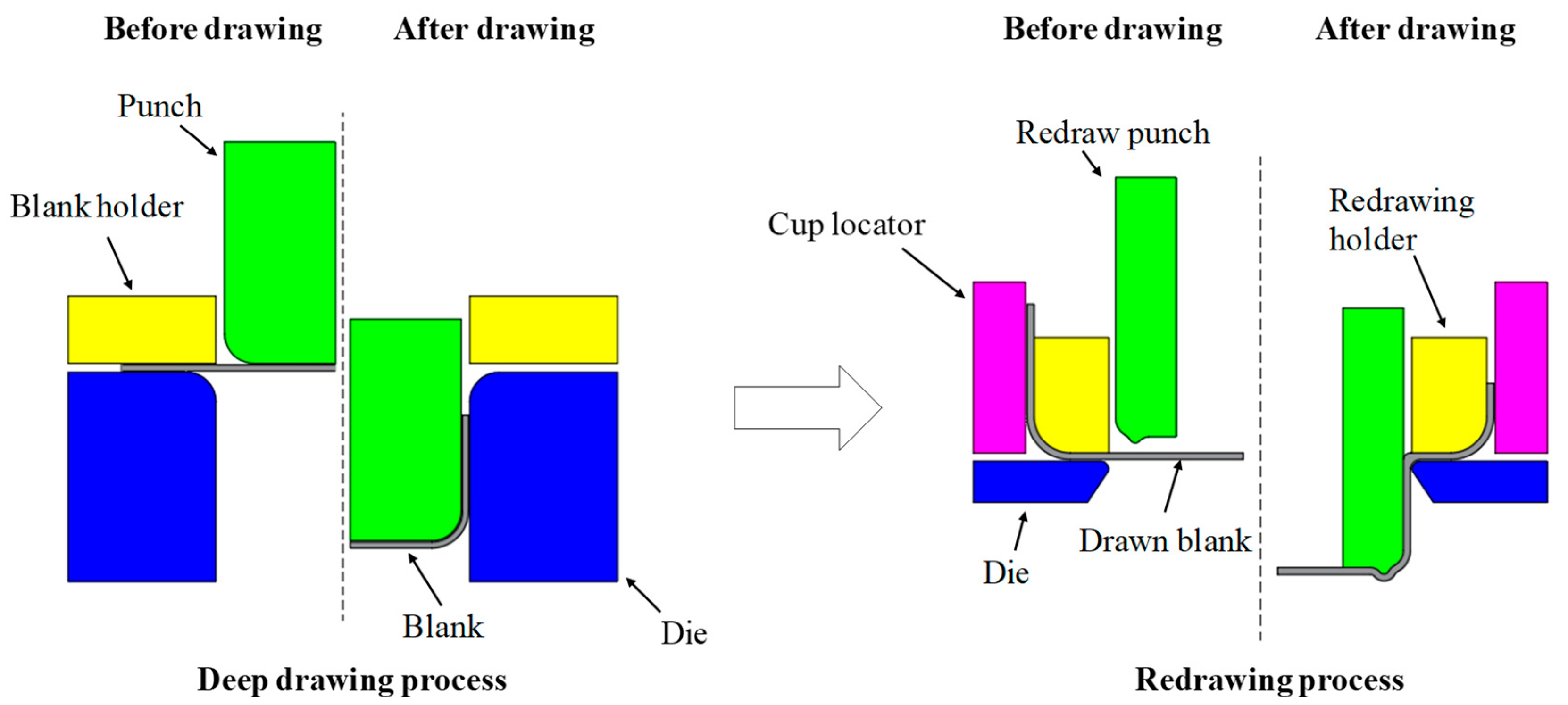

The sheet metal is placed over a die block at which point a punch presses down.

16 kalpakjian design for sheetmetal working ch.

As a result so called second order size effects occur.

In press work large force is applied on thin sheet metals to give the required shape or to cut it in to the desired shape.

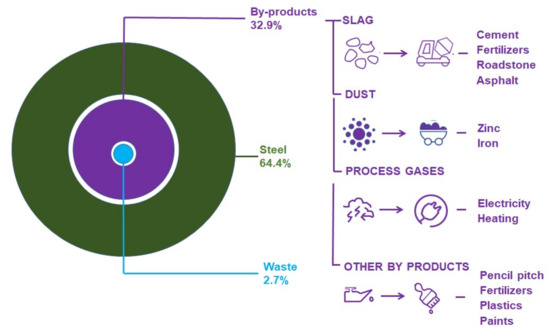

Molten metal from the furnace is taken and poured into metallic moulds and allowed to cool or solidify.

Sheet metal forming 2 810 d.

Ingot is the starting raw metal for all metal working process.

Sheet metal forming involves a wide range of processes that manufacture parts for a vast amount of purposes both seen and unseen.

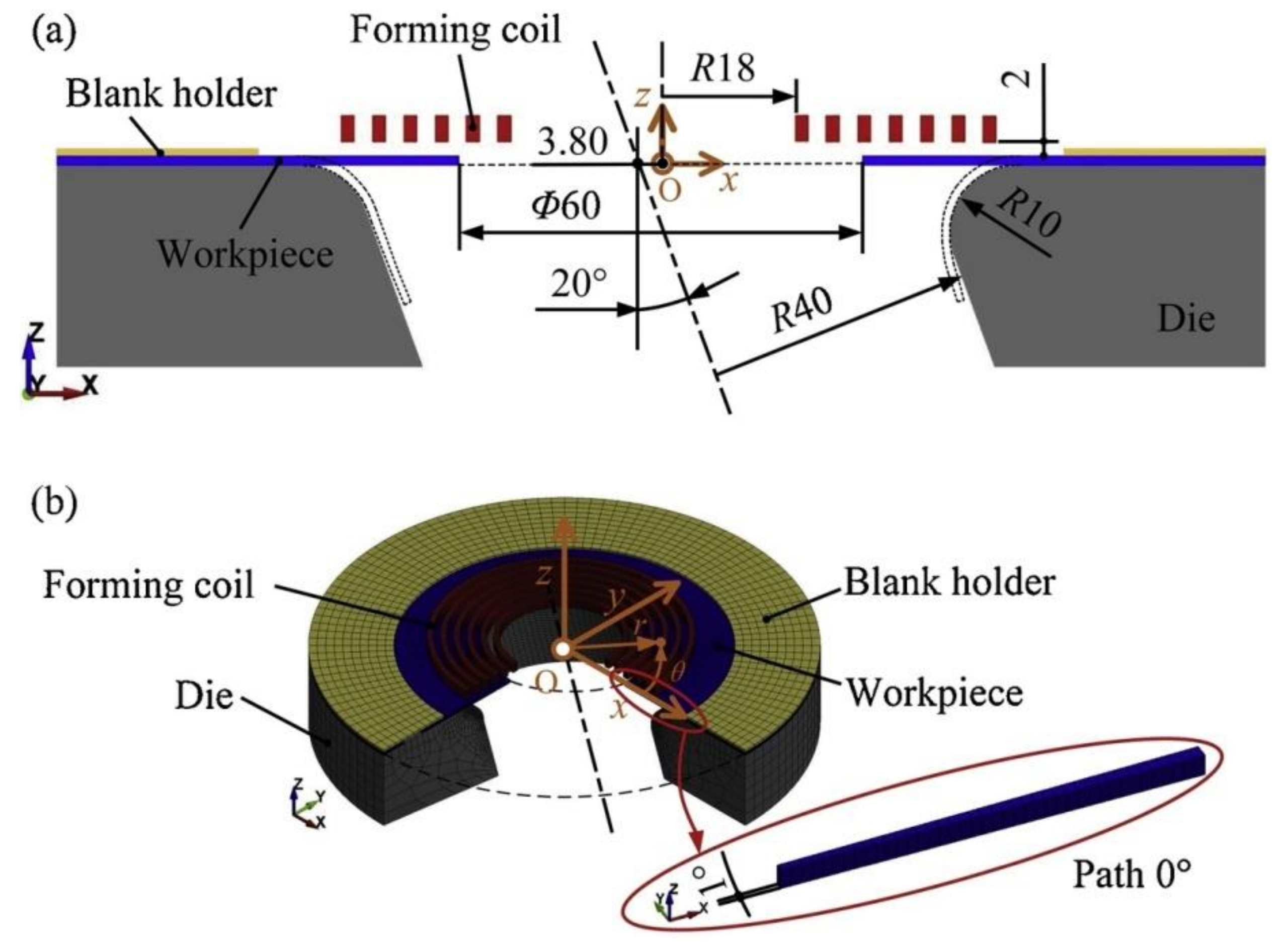

Basic geometry feature of the dieface although an actual dieface is a rather complicated system of surfaces some basic geometry features can be identified.

2002 john wiley sons inc.

Sheet metal work stock used for sheet metal processes is usually formed by rolling and comes in coils.

Press work is highly economical method of manufacturing.

The simplified die addendum.

Such basic features can be summarized as.

Cooper sheet metal forming ch.

As a result so called second order size effects occur.

Curling is a forming process that involves de burring sheet metal to produce smooth edges.

It is defined as the mechanical working of metal at a temperature between that of hot working and cold working.

Another common sheet metal forming process is bending.

Miniaturization of sheet metal working processes causes changes in the relative contribution of relevant process parameters.

The cooled solid metal mass is then taken out of the mould.

Groover fundamentals of modern manufacturing 2 e strain rate sensitivity theoretically a metal in hot working behaves like a perfectly plastic material with strain hardening exponent n 0 the metal should continue to flow at the same flow stress once that stress is reached.

Introduction to sheet metal work.

Introduction to sheet metal forming processes.

The present paper should give a survey of different kinds of second order size effects that can be expected in tensile testing air bending and punching of sheet metal.

Miniaturization of sheet metal working processes causes changes in the relative contribution of relevant process parameters.

Most of the sheet metal work is done on presses where a die and punch or other formed tools are required.

With the use of the industrial manufacturing process sheet metal is formed by working metal into flat and thin pieces sheet metal is one of the very convenient ways that is used in metal working and it can be mended and cut into various shapes and dimensions.